On April 12th, 2022, in Ho Chi Minh City, the Vietnam Electricity (EVN) organizes a conference on Power Sector Automation in Digital Transformation Trend.

On April 12th, 2022, in Ho Chi Minh City, the Vietnam Electricity (EVN) organizes a conference on Power Sector Automation in Digital Transformation Trend.

Participants of the Conference include Mr. Dinh The Phuc - Director of the Energy Department, Commission for the Management of State Capital at Enterprises; Mr. Bui Quoc Hung - Deputy Director of the Department of Electricity and Renewable Energy (Ministry of Industry and Trade); Ph.D. Duong Nguyen Binh – Vice President of Vietnam Automation Association; Mr. Vo Van Yen - Permanent Deputy Secretary of the Party Committee of the Ministry of Industry and Trade in Ho Chi Minh City.

EVN’s participants include Mr. Duong Quang Thanh - Chairman of the EVN's Member Council in charge of presiding over the Conference, members of EVN's Member Council, Deputy General Directors, leaders of offices, specialized departments and divisions, leaders of Corporations and member units of EVN. In addition, there are many other partners from domestic and foreign corporations and companies in the field of energy and technology, engineers and technical experts of units exhibiting and introducing products.

Mr. Duong Quang Thanh - Chairman of EVN's Member Council is making his speech at the Conference

The Conference is held in the both live and online form and is livestreamed on the Fanpage of Vietnam Electricity, Youtube of Vietnam Electricity - EVNNews.

At the Conference, EVN and its member units report the results of their implementation, and at the same time, it is also an opportunity to exchange, discuss, learn from experience and cooperate with partners to create more applications for automation and digital transformation with high efficiency in production and business.

Production process automation will promote and provide high efficiency in operating the power system continuously, safely and stably to further improve the quality of customer services. Currently, EVN has been promoting the application of 4th industrial revolution technology and is determined to basically complete digital transformation by 2022, transforming operations under the digital enterprise model by 2025 with 5 fields of digital transformation consisting of production, business and customer services, construction investment, internal management, telecommunications and information technology (IT).

At the Conference, EVN has announced and awarded 6 Automation Products "Make by EVN" which were researched and developed by its member units. Thereby, 3 products were selected to register for the selection of "Make in Vietnam" products organized by the Ministry of Information and Communications. In the roadmap of implementing the digital transformation, EVN has set a goal of obtaining 10 "Make by EVN" products and 3 "Make in Vietnam" products by 2025.

Mr. Duong Quang Thanh - Chairman of EVN’s Member Council (3rd from the left) and Mr. Ngo Son Hai - Deputy General Director of EVN (2nd from the right) are giving gifts and awarding decisions on recognizing “Make by EVN” products

Participating in the exhibition and presentation at the Conference, EVNGENCO3 has 3 automation products, namely Metal Tank Painting Robot (PM TANKBOT 1), Autonomous Power Conversion Simulation System (ATS) researched and developed by Phu My Thermal Power Company and Automatic Hydrological Data Monitoring, Calculation and Transmission System (BK HYDROLOG) manufactured and installed by Buon Kuop Hydropower Company.

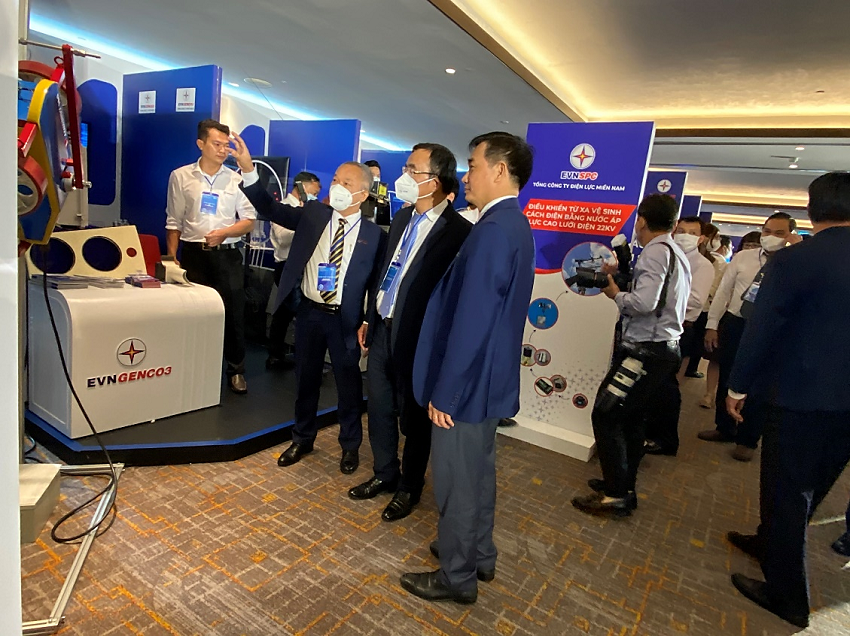

Exhibition booth of EVNGENCO3

PM TANKBOT 1 is researched, designed, manufactured to test, evaluate and paint the surface of metal tanks such as oil tanks, water tanks, lubricating oil tanks in factories. In comparison to the previous method, when painting the tank, scaffoldings must be installed around the tank, using workers to clean and check the painting and tank conditions. Using robots will save costs, labor forces, construction time and especially can guarantee the safety of people when working at the high elevation. In addition, robots can also be used for NDT inspection, internal inspection, tank wall thickness, cooling water pipes, water tunnels and so on by replacing nozzles with corresponding measuring devices and probes.

Leaders of EVNGENCO3 are introducing the Metal Tank Painting Robot (PM TANKBOT 1)

Autonomous Power Conversion Simulation System - ATS is a system that simulates the operating state of a 6.6kV busbar of Phu My 4 Combined-cycle Gas Turbine Power Plant, simulating different operating modes of electrical systems, checking open/closed states, opening/closing speed of the circuit breakers in fast switching mode, normal switching mode and switching mode when a failure occurs; thereby identifying different types of failures to proactively plan to overcome instead of having to detect circuits, analyze relay data, find each fault sequentially, which will take a lot of time. Thanks to the initiative in designs, the system can be extended to simulate any busbar 400V, 6.6kV or other voltage levels of power plants through adjusting parameters and program integration. The system will assure the effective training of new operators, quickly approach and understand intensively about the structure and operating principles of equipment, operating procedures, and actively grasp and integrate experience in operation and troubleshooting activities.

Mr. Cao Quang Quynh – EVN’s Member Council is visiting the booth of EVNGENCO3

The Automatic Hydrological Data Monitoring, Calculation and Transmission System (BK HYDROLOG) is researched, manufactured and installed by the engineer group of Buon Kuop Hydropower Company. The product set includes 3 main devices: a rain meter on the basin, a lake water level meter at the plant and a programmable datalogger to calculate and display water flow data of reservoirs. The System supports the management, operation, regulation and optimal exploitation of reservoirs in the real time, ensuring the safety of works and downstream areas; at the same time automatically transmitting data to the authorities at their request. The system has terminated the manual entry of data with an automatic recording cycle of 15 minutes/time.

Automation products of EVN, EVNGENCO3 and member units at the Conference have contributed significantly to improving the efficiency of production and business activities, increasing the labor productivity, and improving the reliability of power supply, ensuring the publicity and transparency in providing services to customers. The convergence of products at EVN's Automation Conference in 2022 has promoted member units of EVN and the Corporation to continue promoting their creativity and autonomy on the path of automation and digital transformation in the coming period and contributing to the completion of assigned plans.

Some pictures at the Conference:

Leaders of EVNGENCO3 are reporting, discussing and introducing automation products at the Conference

Delegates are visiting booths displaying and introducing products of the Corporations at the Conference

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views