At 23:15 on January 27, 2019, after nearly 2 months of shutdown, the overhaul of GT12 unit was officially handed over to the Load Dispatch Center (A0) for operation, surpassing the delivery schedule by 4 days.

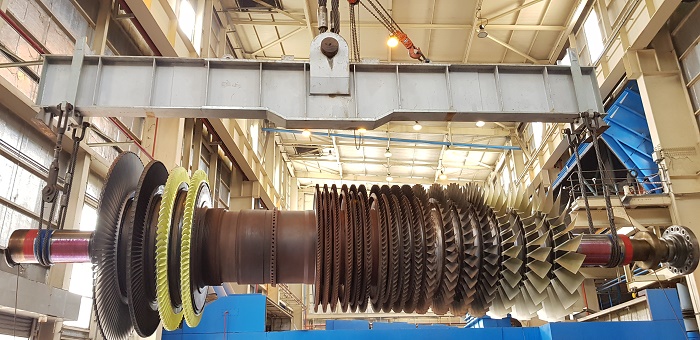

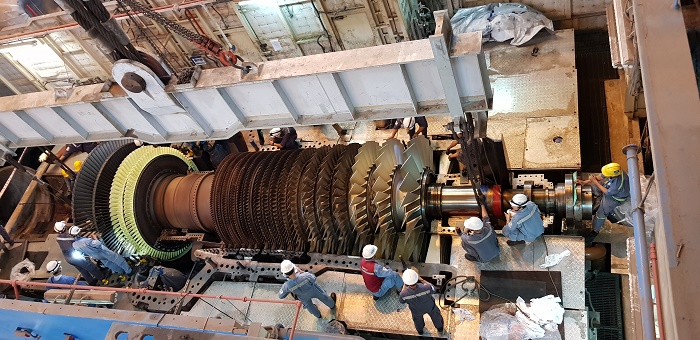

To ensure quality and expedite the completion of the GT12 unit overhaul at Phu My 1 Power Plant, Phu My Thermal Power Company collaborated with EVNGENCO3 Power Plant Services Company (EPS) to work in two shifts per day in order to shorten the schedule. This involved implementing various improvement and equipment upgrade projects to enhance the available capacity and efficiency of the unit, such as replacing hot gas path components to extend the maintenance cycle, installing additional exhaust pipes in the turbine cooling air intake, installing a purge air system on the gas and oil fuel lines to improve reliability during fuel switching. Particularly, together with the MHPS contractor, the successful replacement of the DCS Diasys UP/V control system with Diasys Netmation for Boiler 12 was accomplished.

After nearly 2 months of continuous work and effort, each equipment was checked, maintained, and put into trial operation and testing, meeting all technical requirements. Following the 6-day hot trial period, the GT12 unit was officially handed over to the National Load Dispatch Center for operation and exploitation at 23:50 on January 27, 2019, 4 days ahead of the approved schedule. The shortened downtime for repair allowed for the quick restoration and operation of the unit, contributing to the increased electricity production for the company, meeting the electricity demand during the dry season of 2019, and ensuring the national energy security.

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views