With the utilities that eCAT and WMS bring, Power Generation Corporation 3 has implemented software development, organized testing and gradually put it into operation, serving the standardization of material coding, material allocation, and inventory management throughout the Corporation.

With the utilities that eCAT and WMS bring, Power Generation Corporation 3 has implemented software development, organized testing and gradually put it into operation, serving the standardization of material coding, material allocation, and inventory management throughout the Corporation.

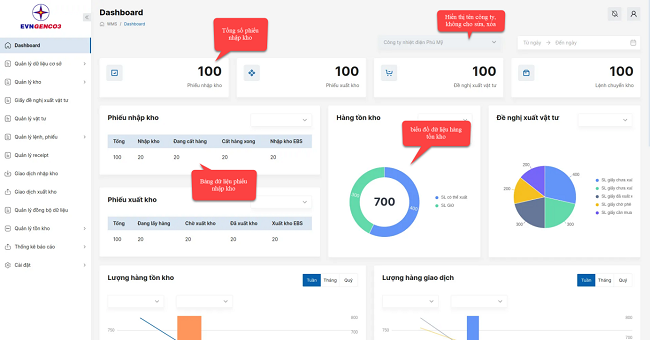

WMS software interface

The process of coordinating the construction of documentation and software design was carried out by the consulting unit along with ideas from dedicated personnel with many years of experience in material management of the Power Generation Corporation 3. Participating from the beginning of the software construction work has maximized the strengths of all parties as well as limited and overcome the existing issues of the current ERP software.

Based on that, Power Generation Corporation 3 assigned DakDrinh Hydropower Company to collaborate with the consulting unit to organize training courses for users on the eCAT and WMS software for all employees to implement material management tasks within the Corporation. The training process is a time for users to familiarize themselves with the program interface, provide feedback to improve business operations, and move towards testing and deployment.

Training users on eCAT and WMS software

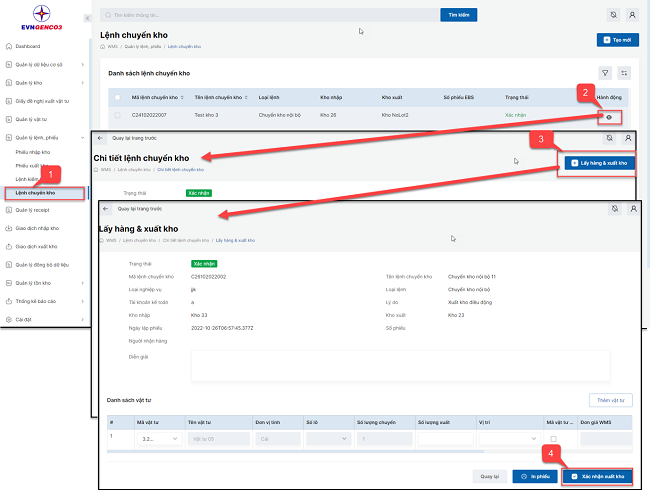

Inventory circulation process in the warehouse

After training, Buon Kuop Hydropower Company continues to be selected as the unit to perform User Acceptance Testing (UAT) and operate each function of the WMS software. Up to now, the company has put into operation some business operations on WMS to enter data into Oracle EBS, moving towards official operation after the software is completed.

After nearly 6 months of implementation, the standardization of the material naming list on the eCAT software is currently being coordinated to eliminate duplicate codes and streamline the naming list, as well as adjust and add new naming items suitable for the current situation and specialized equipment of the entire Corporation. The use of the software has gradually moved towards professionalism in material management, saving time in issuing codes and moving towards a scientific material naming list of the Corporation, while helping employees of the Corporation access advanced management work, suitable for the digital transformation trend of EVN and the Corporation.

The initial successes in using the eCAT and WMS software give us hope for the utilities that the software will bring a scientific and modern material management tool in units and EVNGENCO3.

Buon Kuop Hydroelectric Company

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views

EVNGENCO 3: Chuyển đổi công nghệ, giảm phát thải khí nhà kính

23/07/2025 - 127 views

Buon Kuop Hydropower Company Conducts Fire Prevention and Fighting Drill

17/06/2025 - 96 views