The average height of boilers of large-scale coal-fired power plants is about 60 meters and the total internal volumetric capacity is around 40,000 m3, which are calculated and designed optimally for input coal types.

The average height of boilers of large-scale coal-fired power plants is about 60 meters and the total internal volumetric capacity is around 40,000 m3, which are calculated and designed optimally for input coal types.

During the operation process, failures/malfunctions of boilers often occur such as gas or water leakage at tube heat exchangers, manifolds or discharge pipes etc., therefore, the most important is that it must early and correctly identity locations of damaged pipes and defects to apply appropriate remedies and shorten the downtime for putting boilers into operation as soon as possible. Normally, to ensure the safe operation at this step, a large quantity of scaffolding must be installed, so it takes a lot of time and labor forces.

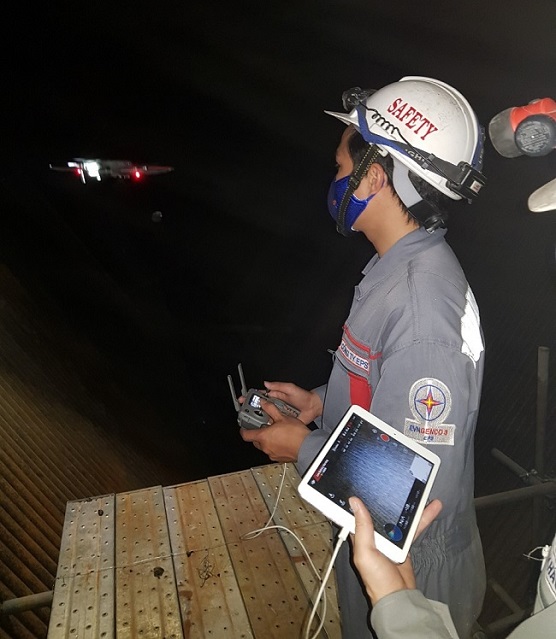

Since 2018, EPS Company - a branch of Power Generation Corporation 3 has researched and applied successfully the furnace assessment technology by Drone Inspection. This technology uses unmanned aerial vehicles, which are designed appropriately to operate in a closed environment and support quick assessments of the boiler status, especially in difficult access locations through visual tracking (VT) from visual video images obtained. This technology helps shorten time and costs for inspection, assessment and repair progress.

EPS’s technicians operate unmanned aerial vehicles

At Vinh Tan 2 Thermal Power Plant (1244 MW), it usually takes 14 days to dismantle and install the scaffolding system in inspection locations of furnaces. By applying the Drone technology to check furnace areas, access to locations such as water walls, dust blowers, burners, air pipes, and grade-2 superheater, the duration for inspection and evaluation progress has been shortened to 7 days and saved a lot of time and costs for the erection and disassembly of the scaffolding. Inspection results are made into database, and periodically monitored and compared by an evaluation and analysis division to promptly find out and handle any damage arising during the operation process in order to guarantee the safe, reliable and permanent operations of boilers.

Technicians control unmanned aerial vehicles to inspect hard-to-reach areas of the power plant

News in the same category

EPS successfully applied the DRONE INSPECTION Technology

16/07/2020 - 57 views